Cooling Systems

LARGE SCALE COOLING CONCRETE PLANT SOLUTIONS

Supplying temperature-controlled concrete for any major construction site is a must all over the world. The development of the strength in concrete is accompanied by evolution of heat as the cement cures and hardens (heat of hydration).

The heat of hydration raises the temperature during the curing process by up to 25° causing an increase of volume. After the curing the concrete cools down, again reducing its volume and thus naturally causing cracks eventually.

Water Chilling Plants

All KTI chillers are highly efficient using three- or four-stage cooling, hot-dipped galvanised evaporative condensers, stainless steel heat exchangers, gauges and panel board and at least two compressors. The power consumption is between 30% and 50% less than conventional water chillers. Each water chiller is equipped with an extra pump for re-circulating the cold water inside the tank through the chillers once the tank is full.

- Power savings up to 55%

- Latest compressor technology

- PLC control with coloured touch screen

- Cost saving installation

Prefrabricated Cold Water Tanks

KTI offers a full range of perfectly insulated cold water tanks, ideally suited for the support of chillers or ice storages with flake ice plants. The necessary stairways and platforms are available in galvanised execution.

Each water chilling system requires a well insulated cold water tank. The size depends on the non-production period of the batching plant.

Prefrabricated Cold Water Tanks

KTI offers a full range of perfectly insulated cold water tanks, ideally suited for the support of chillers or ice storages with flake ice plants. The necessary stairways and platforms are available in galvanised execution.

Each water chilling system requires a well insulated cold water tank. The size depends on the non-production period of the batching plant.

Flake Ice Plants

Flake ice is small ice in flat pieces. It is used in cooling seafood, in meat processing and in a whole range of industrial processes. The most important application of KTI flake ice plants is in the concrete industry, where flake ice is used to control the concrete temperature, particularly in hot climates.

From the cold water tank the water is delivered partly to the scale of the batching plant and partly to the flake ice plants. KTI flake ice plants are installed inside of 40-ft. containers.

- Latest technology of screw compressors

- Energy efficient

- PLC control with coloured touch screen

Combined Flake Ice and Water Chilling Plants

The main advantage of a combined plant (chiller and ice plant in one unit) is that both systems use one common evaporative condenser. The chiller runs with an evaporative condenser which has double the capacity than necessary. This brings the discharge pressure down, lowers the power consumption, and increases efficiency. Over the period of one-year power savings of up to 30 % can be achieved.

- Cost savings 5 % less than individual plants

- Power savings up to 30 %

- Shorter installation

- Less space required

Combined Flake Ice and Water Chilling Plants

The main advantage of a combined plant (chiller and ice plant in one unit) is that both systems use one common evaporative condenser. The chiller runs with an evaporative condenser which has double the capacity than necessary. This brings the discharge pressure down, lowers the power consumption, and increases efficiency. Over the period of one-year power savings of up to 30 % can be achieved.

- Cost savings 5 % less than individual plants

- Power savings up to 30 %

- Shorter installation

- Less space required

Plate Ice Plant

KTI has designed and developed a new universal plate ice plant that can be used in one of three settings: Only ice water, ice water and plate ice and only plate ice.

- Bigger capacities in one container – up to 168 tons/day

- Lower investment costs

- Reduced power consumption

- Conversion from plate ice production to water chilling

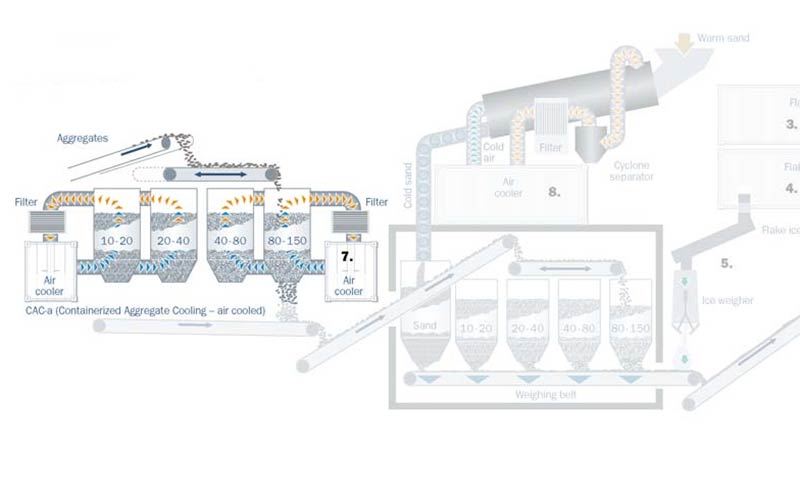

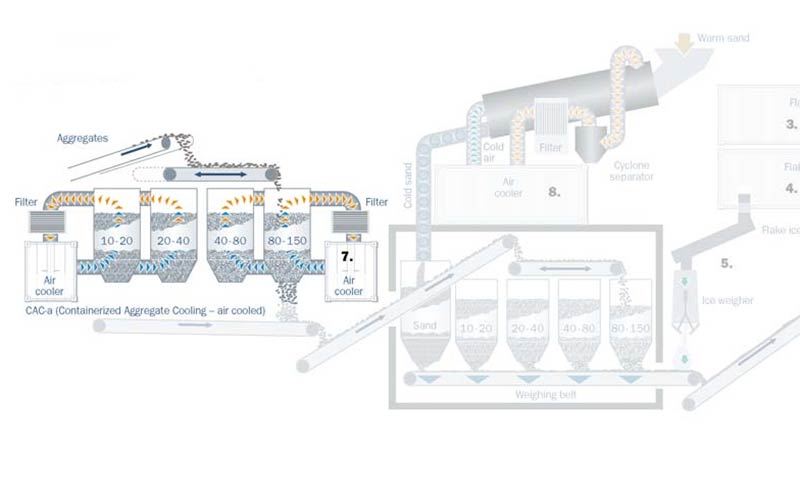

Aggregate Cooling Systems

In most cases the ice addition together with chilled water is sufficient to reach the required concrete temperature out of the mixer.

However, under certain circumstances, it is required to cool the aggregates as well, either by air or cold water.

Aggregate Cooling Systems

In most cases the ice addition together with chilled water is sufficient to reach the required concrete temperature out of the mixer.

However, under certain circumstances, it is required to cool the aggregates as well, either by air or cold water.

Bulldog are here to help

The Bulldog team are on-hand to help find the right solution for your project.

Please call us on 01371 873282 or send us your enquiry.